GLYCODUR® Dry Bearings – Environmentally friendly for over 50 years

Since 1970 we have been manufacturing bearings with layers of self-lubricating material that require either no lubrication or lubrication only at initial installation. Our commitment to the environment extends not only to our lead-free dry bearing material, but to our environment-friendly manufacturing processes.

Our innovative technologies are applied in our sophisticated, state-of-the-art manufacturing and development facilities. These facilities allow us to continually respond to customer demand for standard and customized products designed to improve comfort and reduce maintenance for shock absorbers, hinges, gears, pumps, valves, car seats, vibration dampers and other equipment requiring bearing materials.

The new Product Finder

The product finder is supporting you interactively to select suitable GLYCODUR® bearings and GLYCODUR® materials, by entering your application data, e.g. radial or axial load, type of load and movement, roughness of the sliding partner. You can specifically inform yourself about the proposed materials. Download links to data sheets, certificates or 2D/3D CAD data are available immediately.

Featured Material:

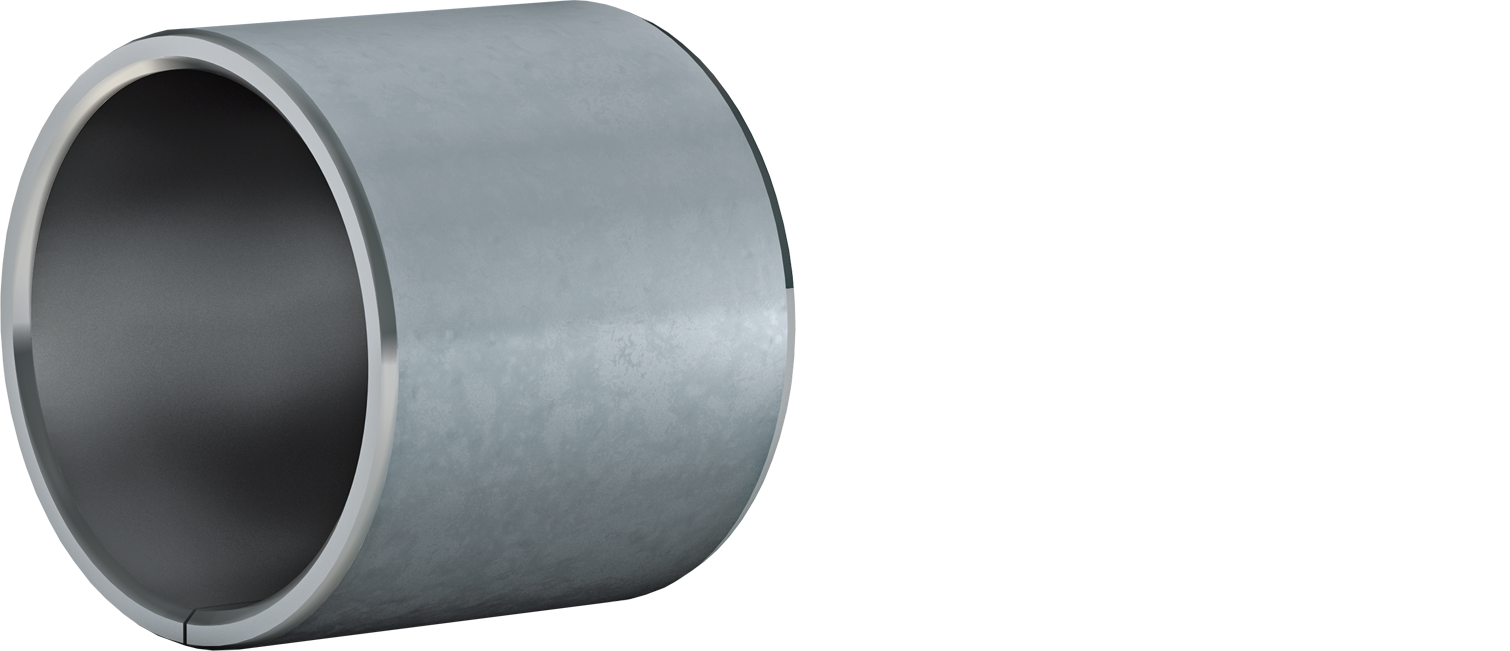

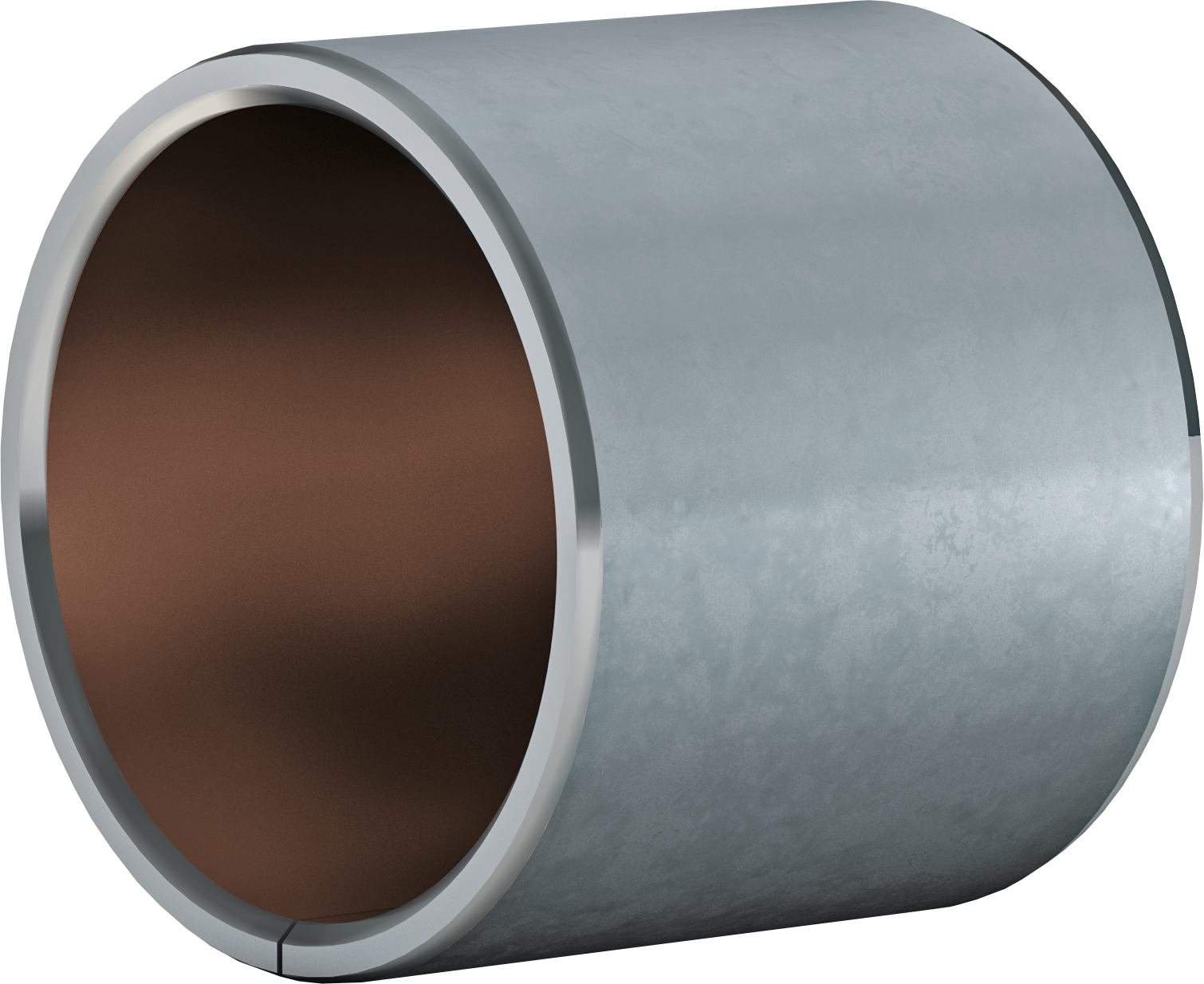

GLYCODUR® F (GLYCO® 92)

- PTFE based according to ISO 3547 type P1

- Negligible stick-slip effect

- 250 MPa maximum static load

Catalog parts

- GLYCODUR® F

- Cylindrical bushings

- Flanged bushings

- Thrust Washers

- Strips

- GLYCODUR® A

- Cylindrical bushings

- Thrust Washers

- Strips

Materials of the

GLYCODUR® Portfolio

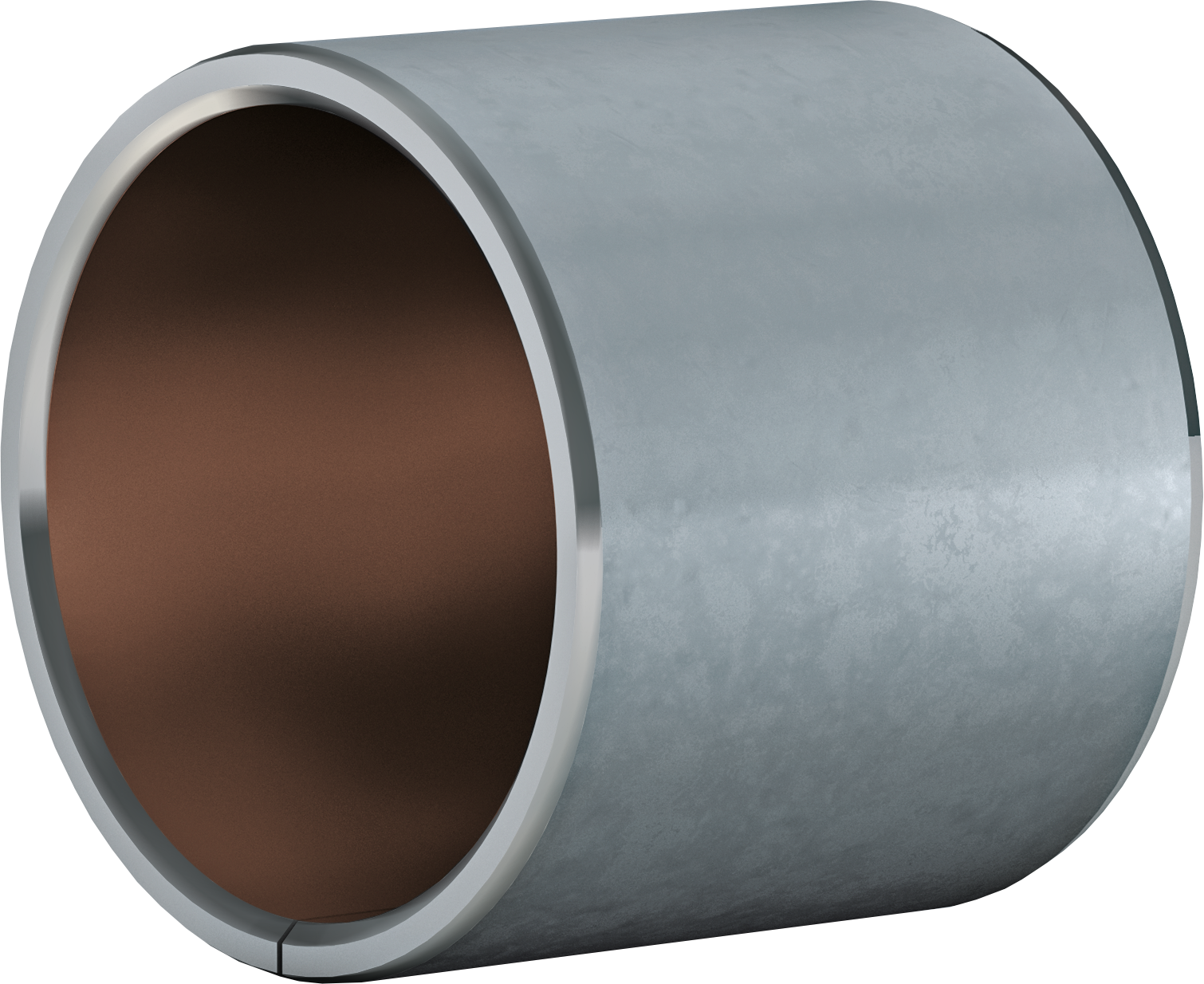

GLYCO® 193 – Thermoplastic based according to ISO 3547 type P2

GLYCO® 193 is a three layer composite material. A porous tin bronze sinter structure is applied on a steel back.

[Learn more]

GLYCO® 290 is based on a steel-expanded metal impregnated and covered with a highly loadable polymer compound based on PTFE and thermoplastic materials giving improved wear and friction properties under dry running conditions.

[Learn more]GLYCO® 393 – Thermoplastic based according to ISO 3547 type P2

GLYCO® 393 is a three layer composite material.

[Learn more]