GLYCO® 97

Key Features

- Maintenance-free operation lubrication for use under severe dry running conditions

- High pv-value

- Good wear resistance

- High load capacity

- Low friction

- Rotating, oscillating and axial motion possible

- Wide range of part design types

For some applications operated without any lubrication, maintenance free bearings do not achieve the targeted service life. Performances in friction improving the system efficiency are also below expectations.

Reasons could be the use of standard performance PTFE-materials, not optimized for dry running conditions at higher loads and long operation periods.

GLYCO® 97 is a three layer composite material. A porous tin bronze sinter structure is applied on a steel back. This layer is impregnated with a PTFE sliding material and a specific combination of fillers especially chosen to improve the performance of this material under dry running conditions. On the top of this filled bronze structure, a 5 to 30 μm thick overlay of the same sliding material is applied, providing the initial lubrication during the running-in of the application.

GLYCO® 97 sliding bearings are therefore showing lower friction and in the same time higher wear resistance under dry operation compared to other standard PTFE-based materials. In addition, it is available on request with a thinner top layer offering advantages for applications involving a cataphoretic painting process.

Microsection

Microsection GLYCO® 97 according to ISO 3547 type P1

| 1 | PTFE, MoS2, BN with friction reducing additives |

| 2 | Tin bronze |

| 3 | Steel back |

| 4 | Tin layer (optional) |

Technical Data

| Properties | GLYCO® 97 |

|---|---|

| Material type | PTFE based according to ISO 3547 type P1 |

| Composition | Steel back with sintered layer of tin bronze. Pore filling and cover layer (5 to 30 µm/0.0002 to 0.00118 in) of PTFE, MoS2, BN with friction reducing additives |

| Application | Optimised dry bearing material, good formability. Automotive dry running systems like vibration dampers, actuators, various hinges (door, trunk lid, hood, convertible roof), locking devices, pedal systems. |

| Permissible stat. specific load | 250 MPa |

| Permissible dyn. specific load | 100 MPa |

| Maximum sliding velocity |

2 m/s (dry running) |

| Operating temperature | -200 to 260 °C |

| Coefficient of friction | 0.09 to 0.20 (dry running) |

| Stick-slip | negligible |

| Wear layer thickness (min.) | 0.2 mm / 0.0079 in |

| Lubrication

Friction Wear resistance Load capacity |

dry

++ ++ ++ |

| Ability to support edge loads (resulting from misalignment) | standard |

| Ability to embed dirt and foreign particles | standard |

| Ability to carry alternating loads | good |

| Ability to accommodate linear movement | standard |

| Machining of sliding surface after mounting | calibration |

| Technical sheet |

Available Designs

All Materials of the

GLYCODUR® Portfolio

Catalog parts

- GLYCODUR® F

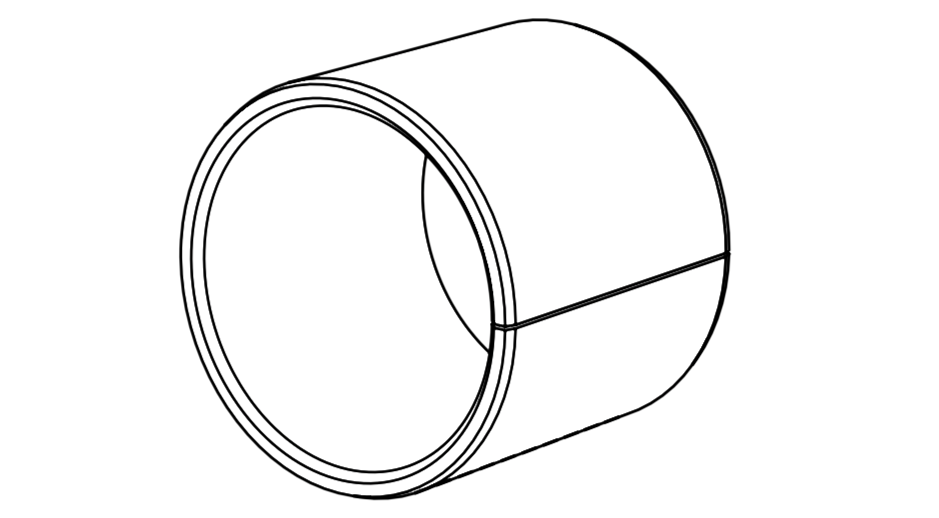

- Cylindrical bushings

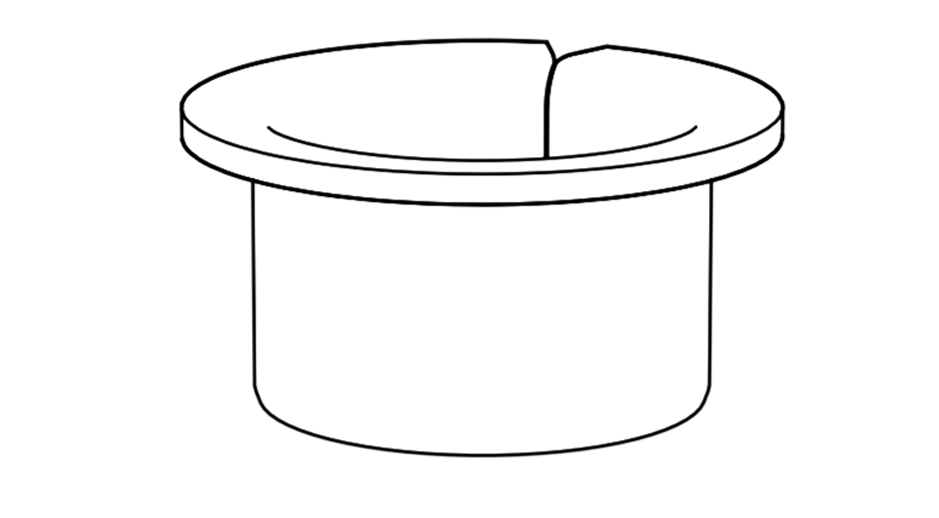

- Flanged bushings

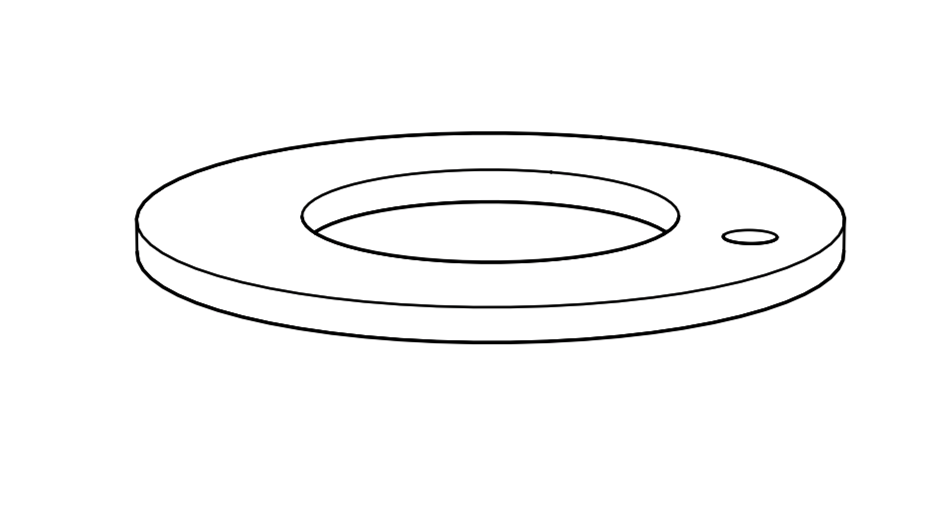

- Thrust Washers

- Strips

- GLYCODUR® A

- Cylindrical bushings

- Thrust Washers

- Strips